|

|

#1 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

Gio Monster 150 Rear Axle Repair

I put about 20 hours on our Gio Monster 150 before it started to squeak a little in the rear axle.

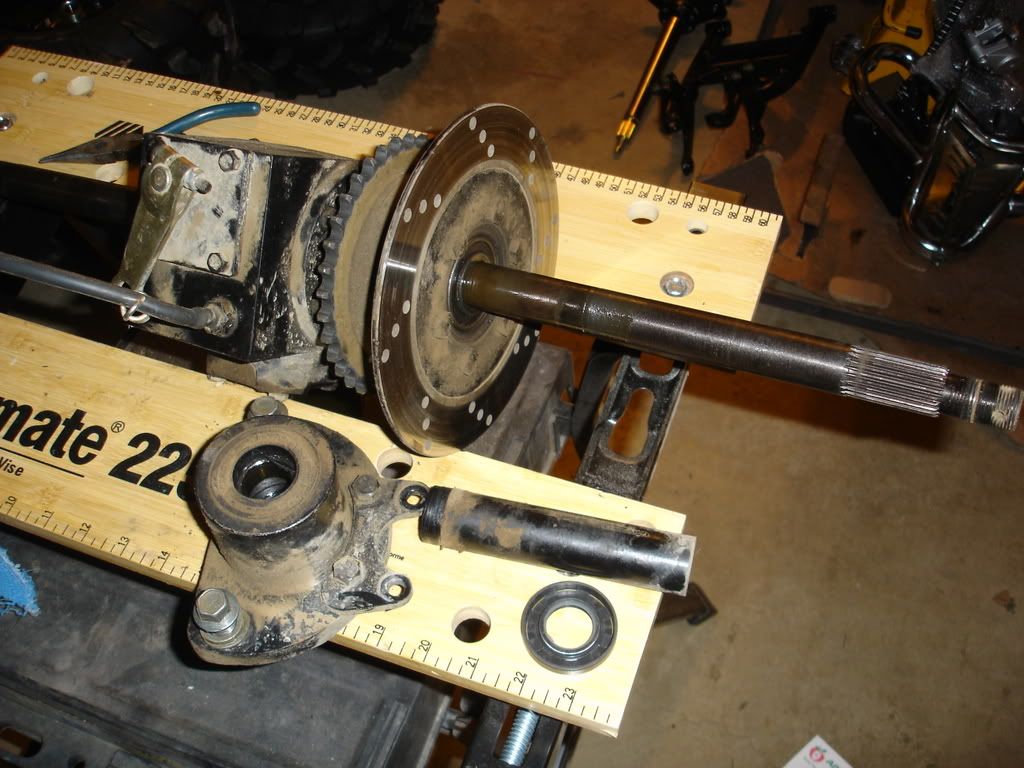

When I did the PDI, I drained out what can only be described as a vile concoction that smelled like wood preservative with the viscosity of molasses. I then filled it with Castrol Syntec 75W90 gear oil (about half full, since there's no clear fill amount). I decided to dismantle it to see what was causing the squeaking, and it turned out to be the outer two bearings. They are tapered rollers, much like a car or trailer, and they weren't packed in grease, only squirted with oil. Apparently bearings will live 20 hours that way. :? The rest of the rear axle had sealed bearings in it, and they were fine. The rear axle on the Monster has a reverse gear in it, and the gears live in gear oil. That environment is sealed via the sealed bearings, and then the sealed bearings are sealed from the tapered rollers, and the tapered rollers are sealed from the outside world. The design is quite ingenious. It has two ring gears that face one another, and the pinion gear floats between the two on a hardened pin. The shift fork that slides the pinion gear is actuated by a cable and lever. You simply stop, pull the lever all the way back, and you're in reverse. The only bummer about the repair was that the tapered rollers were some weird metric size that cost me $50 for the pair. Otherwise, it was no problem. The following view shows the odd box-shaped differential housing, the reverse lever and the detached left side bearing housing. That tube to the right of the bearing housing needs to be installed to mate with the seal.  The next shot shows the right bearing housing, and how the tapered roller is only on the outside. You can also see two sealed bearings stacked in the bottom. This is the side that is next to the sprocket.  The next shot shows the new bearings ready for installation. They must be properly packed with good quality grease. I also removed the paint from the tube so that the tube could spin easily inside the seal. I apply grease over the tube and seal transition once everything is reassembled.  After seeing the rear axle apart, I decided that if a gear was to be chipped, I'd never find a replacement, so I bought another complete rear axle for a spare. The price was right. This is a good alternative to the dune buggy planetary reverse mechanisms. I'm not saying that this is better, but it is certainly robust. We all know that this was copied from something, the question is what? Any ideas? Also, anybody else have a 150 GY6-based quad?

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#2 |

|

Join Date: Jun 2009

Location: orbital platform

Posts: 741

|

After the purchase of my GY6 engine I was looking at reversing options. The way this was done on the Monster (what your write-up and pictures describe) appears to be an anomaly. The "usual", including the latest way GIO is doing it now, appears to be mounted on the GY6 output shaft.

How others are doing it: http://www.buggydepot.com/buggy-tech...-Crossfire/17/ (sorry you have to download the instruction sheet) Latest GIO type: http://www.giobikes.com/Engines-Comp...extGen-Engine/ (take a look at the pictures of the complete GY6 engine) This way (found on the GIO Monster) would appear to be about 100% stronger. |

|

|

|

#3 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

That's what I mean by planetary reverse mechanisms. Which unit are you saying is 100% stronger?

The rear axle that our Gio has was the way they did it in 2006. Gio didn't offer a planetary type then. So far, this rear axle has been very reliable.

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#4 |

|

Join Date: May 2006

Location: Fredericton, NB, Canada

Posts: 1,744

|

Another excellent post.

I'm stickying this sucker...

__________________

Frostbite "The beatings will continue until moral improves" |

|

|

|

#5 |

|

Join Date: Jun 2009

Location: orbital platform

Posts: 741

|

Which unit are you saying is 100% stronger?

This one, the one you wrote up about, the planetary systems, on the whole, aren't too strong, though the new GIO system seems stronger than the other planetary systems out there. |

|

|

|

#6 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

The major component in reliability is how reverse is used. If you're in the habit of yanking the reverse lever for powerslides, don't expect longevity.

My kids have been taught to come to a complete stop, pull the lever, ease on the throttle until you feel it engage, then give 'er. Same rule applies to switching into forward.

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#7 |

|

Join Date: Sep 2008

Location: Surrey, B.C., Canada

Posts: 2,185

|

Oh come on, let the kids have some fun with some rockfords! 8)

|

|

|

|

#8 |

|

Join Date: Oct 2009

Location: Newmarket On Canada

Posts: 382

|

HIJACK: I have a Workmate 400, still going strong, remember them?

Very nice write up. I almost wish my Beast had a similar rear end just so I could do the mod  Pete |

|

|

|

#9 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

I always wanted a 400; didn't they have the one-handed mechanism?

Be glad that the Beast axle is anvil-simple. Two bearings only, and they're cheap.

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#10 |

|

Join Date: Sep 2008

Location: Surrey, B.C., Canada

Posts: 2,185

|

Something tells me my mini beast axl is coming apart soon, have to take some photos and share the 'guts' to find out whats binding up in there...

D, I forgot to look for something for you today. My apologies. This reminded me of it, I'll call pops tomorrow and ask him about the hand hones. |

|

|

|

#11 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

No rush T. I'm gonna take my time with Sam's 200 engine. Let me know if you need help with the axle.

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#12 | |

|

Join Date: Sep 2008

Location: Surrey, B.C., Canada

Posts: 2,185

|

Quote:

|

|

|

|

|

#13 |

|

Join Date: May 2010

Posts: 16

|

I have this exact same gearbox. I was wondering why reverse was clunking and forward was OK.

I completely disassembled my gearbox and found out what the problem(s) were. Break out your Dremel polishing and light grinding bits. I will do a complete write up on this soon, but right now I am very busy. Basically, it is a very well built and sturdy design, but there is no phrase in Chinese for "Finishing touch". Components that should have a mirror polish are rough as sandpaper. Also, there is a dog that pushes a multi fingered pawl into one of two spider gears that selects which direction the axle will rotate. The dog is against a pretty strong spring. In order to successfully go into reverse, you not only have to overcome this strong spring, but also overcome any mechanical friction in the mechanical circuit. The single biggest cause of my failure was a worn out engagement spring that is attached to the reverse cable. A stronger spring is simply mandatory. More to come in this thread or my thread.. |

|

|

|

#14 | |

|

Join Date: May 2010

Posts: 16

|

Quote:

If you take off the 4 bolt block in the back, where the 3rd spider gear and bearing are held, you will see the shift mechanism. This is the only way you will know if you are getting full engagement of reverse. (I thought PTO when I took this block off!) The internal engagement of reverse should be instantaneous and full when power is applied. If you rev it to the moon and pop the clutch you WILL break the reverse assembly. Normal application of the throttle shouldn't cause trouble. The spring attached to the reverse actuation cable (Outside of the box) is weak and should be replaced no matter how well you think your reverse is working. I will let you know how well the spring I bought works. More when I have time. |

|

|

|

|

#15 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

Thanks for your feedback!

The external spring that is attached to the cable is pretty stout on ours. Reverse and forward both engage smoothly and quietly. Maybe the Castrol Syntec 75W90 helps. I didn't polish the gears, but I look forward to your procedure.

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

|

|

|

|