|

|

#1 |

|

Join Date: Jun 2008

Posts: 293

|

When a 20 minute job takes you all day

I made the attempt to fix a stripped bolt hole yesterday. Right in the middle of it I got a super important world is going to end phone call from work. The stripped hole stuff set way to solid around the bolt. Even slowly working the bolt back and fourth it eventually went PING and snapped. I still haven't gotten the broken bolt out. I thought it would be easier to take the magneto cover off, but in retrospect It will be easier to drill it on the bike as I do not have a drill press. I still haven't figured out how to take off the seat. It looks like it may be buried under several layers of 'stuff'.

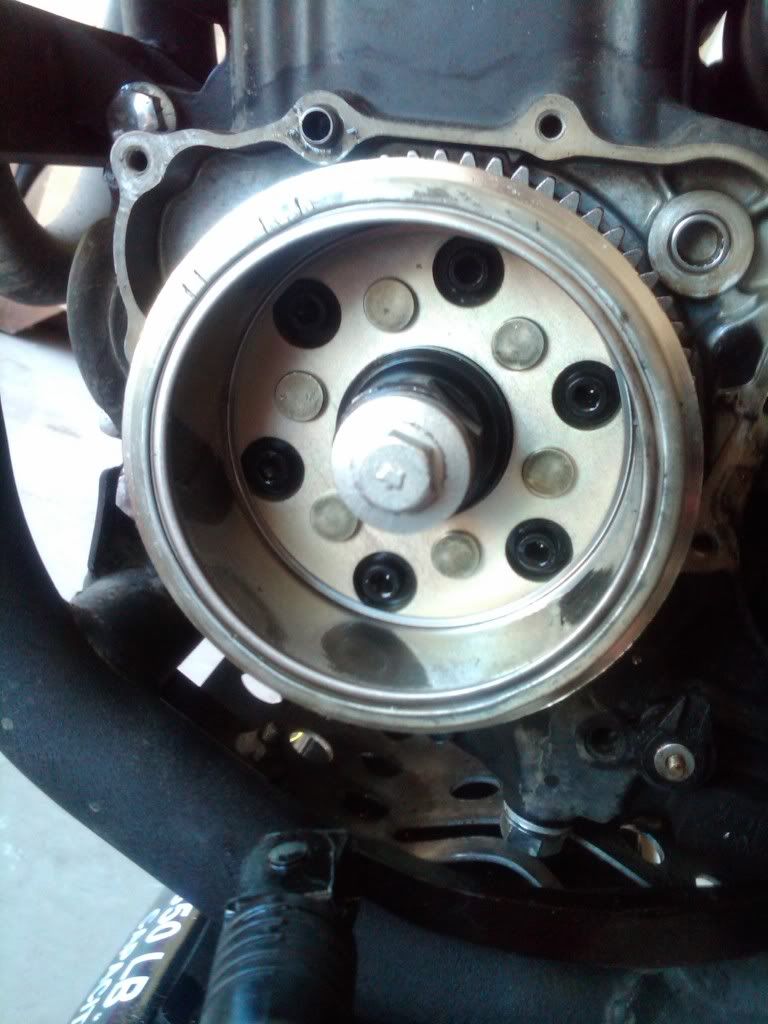

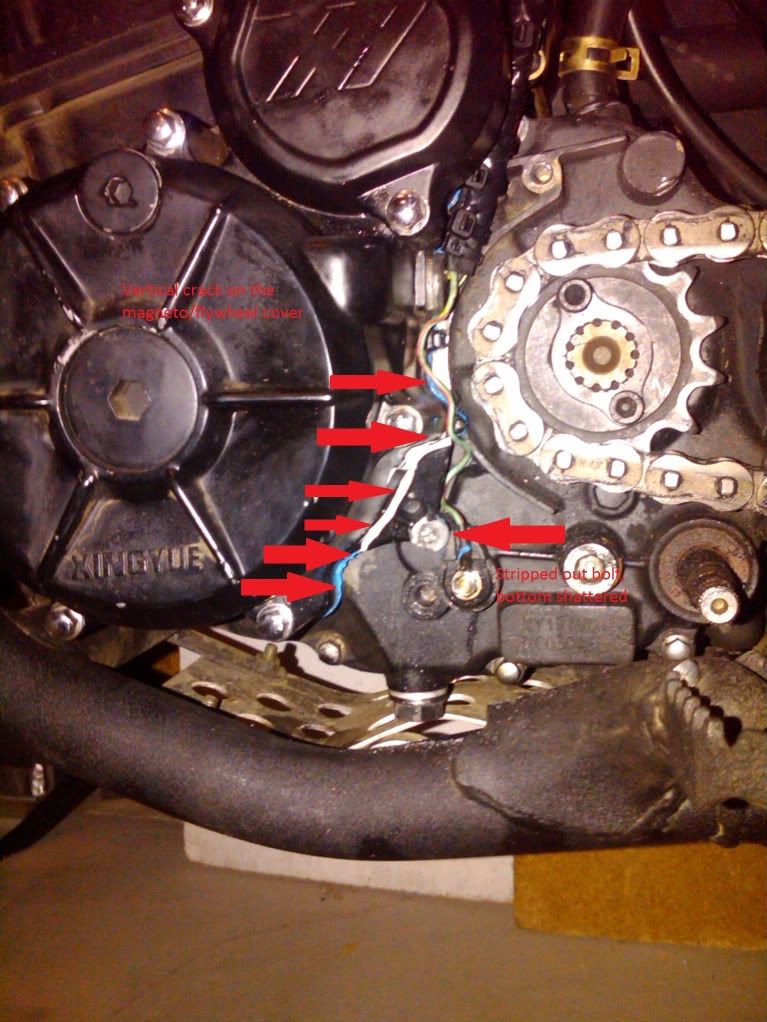

When I removed the magneto cover it became very obvious how the threads got stripped in the first place. From the factory, too long of a bolt was used. It bottomed out against the rest of the engine and would never get tight so I'm thinking whatever tool was used to initially put it on there spun it around a bunch, but the blue loc-tite caused it to stick. Zooming in views red arrows show the broken bolt: First pic illustrates where the bolt is that broke off.  Closer up view:  Super zoom:  Inside of the magneto cover (only because Spud would say "too bad we didn't get a pic of the inside of the magneto cover"  Flywheel  I'm going to post an "I admit I'm a bonehead" question on the Pitster forums to see if I can get a good how-to on seat removal. Until then, I've got a few ideas on how to keep the drill bit centered while I drill that old bolt body out. Whatever those bolts are made of, the do not like to drill..... Daddy 8) |

|

|

|

#2 |

|

Join Date: May 2006

Location: Fredericton, NB, Canada

Posts: 1,744

|

Whatever you do, _please_ don't use an easy-out/extractor. That way lies damnation.

__________________

Frostbite "The beatings will continue until moral improves" |

|

|

|

#3 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

Have you tried a cobalt bit? They'll usually chew through anything.

What's with the skidplate? It looks like it's bent up towards the drain plug. Your countershaft sprocket has 11 teeth, and it's unlike any other that I've seen. I'm still no closer to the origins of this engine. :? [/quote]

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#4 |

|

Join Date: Aug 2010

Location: Olympia, WA

Posts: 36

|

Maybe the Chinese have hired some, brace yourself, engineers to design this motor. If this is a harbinger of things to come, we oughta see some pretty good stuff in the future. Looks nice anyway, hope they are bullet-proof as well.

Cobalt bits are it when drilling out the forsaken easy-out. They will be destroyed in the process as they are extremely brittle and will only work with patience - be careful!

__________________

Member: Zongshen world domination plot. |

|

|

|

#5 |

|

Join Date: Jun 2008

Posts: 293

|

Ez outs..... I've only used 1 successfully in my life. Every other time they have made the problem much much worse. I'll have to search out some cobalt bits and WD-40 and go to town. I just need it out of there, any other suggestions?

Daddy 8) |

|

|

|

#6 |

|

Join Date: Mar 2009

Location: Southeastern Washington desert

Posts: 14,761

|

Reverse drill bit. Many times they will actually remove the broken bolt just by using them.

__________________

Happy to serve. |

|

|

|

#7 |

|

Join Date: Aug 2010

Location: austin, tx

Posts: 1,452

|

feel your pain dude, i was checking out my oil filter on the quad, the shifter was in the way so i went to remove it and snap the bolt that tightens it around the shift rod snapped off in the shifter.. that was mid afternoon and then about 4am i finally got the bolt drilled out, but some of it was left in it. so i removed the shifter and drilled it out some more eventually got it and the hole was big enough to put a large bolt with a lock washer on it..

youtube search removing a broken bolt, some great how to videos there that make it look all to easy |

|

|

|

#8 |

|

Join Date: Oct 2009

Location: Alberta, Canada

Posts: 3,274

|

Is the broken bolt sticking up enough to snork a set of vice grips on it? I have had good success with that method provided that the bolt isn't too tight. Hoping you can get it out without too many expletives.

Cheers, Stew |

|

|

|

#9 |

|

Join Date: Aug 2010

Location: austin, tx

Posts: 1,452

|

if the bolt is sticking out enough you could always do a little tack weld to another bolt and see if that can back it out

|

|

|

|

#10 | |

|

Join Date: Mar 2010

Location: Volcano, Ca

Posts: 7,078

|

Quote:

It's now runs on 1 bolt wth a snapped EZ-out in the other cross-threaded hole. :oops: :x That is one big QC thing I've found on the CB's that are like no other. Some of the bolts are truly made of hard cookie dough. Extreme metal quality inconsistencies.

__________________

"Light a fire for a man, and you heat him for a day. Light a man on fire, and you heat him for the rest of his life." 2007 Suzuki DRZ400S (SM convert) 2009 Q Link XP 200 1967 BSA B25 250cc Starfire 2022 Royal Enfield Interceptor 650 2023 Royal Enfield Scram 411 1948 Royal Enfield Model G 350 |

|

|

|

|

#11 |

|

Join Date: Jun 2008

Posts: 293

|

***Disclaimer***

I never swear. I just don't. There are so many better words out there when something goes horribly wrong. I swore today:  I dang near had the old bolt out. I was alternating between the drill and the center punch. I brought the wrong hammer.... I had to walk away from that the rest of the evening. I'm going to assess the damage in further detail tomorrow. It looks like a clean crack and if it is I'm going to JB Weld it in true chinariders fashion Bah! Daddy 8) |

|

|

|

#12 | |

|

Join Date: Jun 2008

Posts: 293

|

Quote:

Daddy 8) |

|

|

|

|

#13 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

Know anyone with a TIG welder? That would make for a nice, clean leak-free repair.

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

#14 | |

|

Join Date: May 2006

Location: Fredericton, NB, Canada

Posts: 1,744

|

Quote:

__________________

Frostbite "The beatings will continue until moral improves" |

|

|

|

|

#15 | |

|

Join Date: Sep 2008

Location: Nashville, TN

Posts: 588

|

Quote:

Hope you can get it repaired. Bill R |

|

|

|

|

|

|

|

|