|

|

#1 |

|

Join Date: Mar 2009

Location: Sardis, BC, Canada

Posts: 25,977

|

Gio Monster 150 Rear Axle Repair

I put about 20 hours on our Gio Monster 150 before it started to squeak a little in the rear axle.

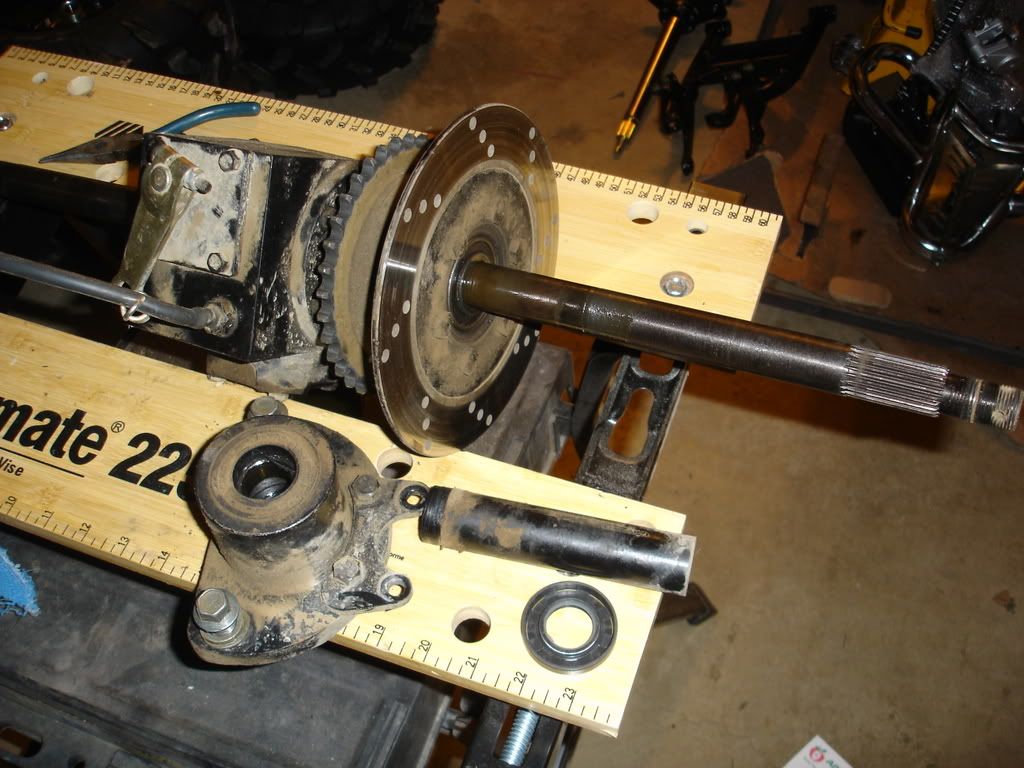

When I did the PDI, I drained out what can only be described as a vile concoction that smelled like wood preservative with the viscosity of molasses. I then filled it with Castrol Syntec 75W90 gear oil (about half full, since there's no clear fill amount). I decided to dismantle it to see what was causing the squeaking, and it turned out to be the outer two bearings. They are tapered rollers, much like a car or trailer, and they weren't packed in grease, only squirted with oil. Apparently bearings will live 20 hours that way. :? The rest of the rear axle had sealed bearings in it, and they were fine. The rear axle on the Monster has a reverse gear in it, and the gears live in gear oil. That environment is sealed via the sealed bearings, and then the sealed bearings are sealed from the tapered rollers, and the tapered rollers are sealed from the outside world. The design is quite ingenious. It has two ring gears that face one another, and the pinion gear floats between the two on a hardened pin. The shift fork that slides the pinion gear is actuated by a cable and lever. You simply stop, pull the lever all the way back, and you're in reverse. The only bummer about the repair was that the tapered rollers were some weird metric size that cost me $50 for the pair. Otherwise, it was no problem. The following view shows the odd box-shaped differential housing, the reverse lever and the detached left side bearing housing. That tube to the right of the bearing housing needs to be installed to mate with the seal.  The next shot shows the right bearing housing, and how the tapered roller is only on the outside. You can also see two sealed bearings stacked in the bottom. This is the side that is next to the sprocket.  The next shot shows the new bearings ready for installation. They must be properly packed with good quality grease. I also removed the paint from the tube so that the tube could spin easily inside the seal. I apply grease over the tube and seal transition once everything is reassembled.  After seeing the rear axle apart, I decided that if a gear was to be chipped, I'd never find a replacement, so I bought another complete rear axle for a spare. The price was right. This is a good alternative to the dune buggy planetary reverse mechanisms. I'm not saying that this is better, but it is certainly robust. We all know that this was copied from something, the question is what? Any ideas? Also, anybody else have a 150 GY6-based quad?

__________________

Weldangrind "I figure I'm well-prepared for coping with a bike that comes from the factory with unresolved issues and that rewards the self-reliant owner." - Buccaneer |

|

|

|

|

|

|